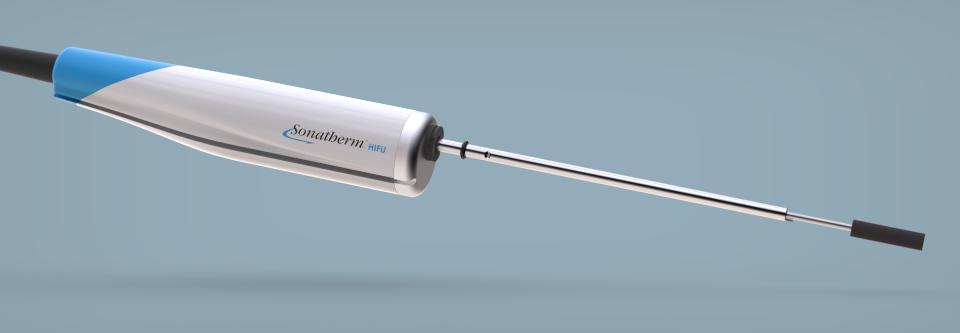

Laparoscopic probes manufactured by Sonablate Corporation allow doctors to destroy cancerous tissues using high-frequency sound waves—eliminating the need for radiation and often eliminating the need to make a surgical incision. To make their Sonatherm® probe more appealing, easier to clean, and cost-effective to manufacture, Sonablate engaged Daedalus to design and engineer a new injection-molded enclosure. This enclosure would contain the proven component assembly, allowing Sonablate to use both existing stock and future production assemblies.

Our mechanical engineers and industrial designers collaborated to achieve Sonablate’s objectives while integrating a host of production-easing mounting and structural features on the interior. Our team also introduced convenient external routing channels for the probe’s disposable tubing, greatly improving the user experience, while maintaining the enclosure’s crucial sealing. The switch to injection molding and its associated benefits, along with a smartly minimized number of enclosure parts, led to the customer enthusiasm and cost savings that Sonablate was hoping for, propelling the surgical ablation system into a successful second generation.