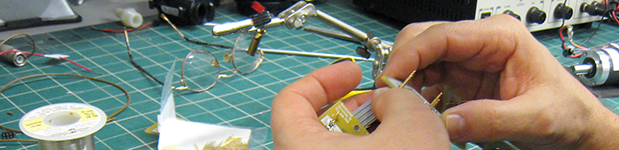

Our prototype shops are equipped to produce prototypes at the right level of fidelity for the specific purpose of the prototype. We routinely make rough gestalt models to evaluate size, weight, ergonomics, and stylistic variations. With our in-house 3D printers, we generate show-quality parts with the accuracy to test fit and function. Close ties with local contract manufacturing firms allow a rapid first turn of a PCB or subassembly, and by maintaining close relationships with craftsmen, model-makers, artisans, and contractors we regularly produce challenging prototypes on the most demanding timetables.

When it is time to validate a design and verify that it meets specifications, we conduct drop/impact, ultimate strength, vibration/shock, temperature, and life cycle testing. For more advanced testing needs, including RFI/EMI/FCC compliance and OSHA/CSA/FDA safety testing, we partner with specialized testing houses and provide summary reports with mitigation strategies as needed.